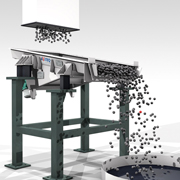

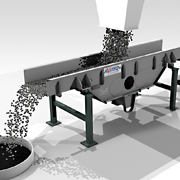

discharging, feeding, conveying

Vibrating conveyors have proven their worth over decades in use with bulk materials: in transportation, in continuous or batch controlled feeding or in dosing. The design of our devices and the materials used to manufacture them are determined by application, grain size, material density and bulk material characteristics.

Our product portfolio includes the following types: