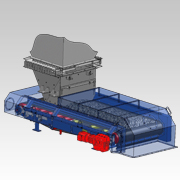

Belt weigh feeders - Weighing

Whether for large or small conveyed quantities, no matter the application, from luxury food processing to the steel industry, AViTEQ Belt weigh feeders assure high weighing precision for reliable, uninterrupted operations. In automated production processes requiring constant weighing and metering, Weiteq Belt Weigh Feeders are the first choice.

Advantages and benefits

- For feeding a wide range of bulk materials from free flowing to bridging

- High long- and short-term accuracy

- Robust construction allows ease of installation and belt replacement

- Customized feeder sizes, belt type and feed hopper based on bulk material handling experience

- Special solutions for high-accuracy feeding and heavy duty operating condition

- Can be used with different types of feeding equipment and directly at the silo outlet

Application

- Components feeding for blending

- Feeding of additives

- Batch charging

- Wagon and truck loadingFeeding and control systems for mills, crushers and mixers

| Technical data | WBL-L | WBF-M | WBF-H |

|---|---|---|---|

| Belt width (mm) | 300 - 800 | 800 - 1400 | 1200 - 2000 |

| Pulley centres (mm) | 1300 - 4000 range of 200 | 1500 - 6000 range of 200 | 2000 - 10000 range of 200 |

| Feed rate max. (t/h) | up to 30 | up to 200 | up to 1500 |

| Control range | 1:10 / 1:20 / 1:50 | 1:10 / 1:20 / 1:50 | 1:10 / 1:20 / 1:50 |

| Accuracy actual value (%) | ±0,5 (±0,25 on request) | ±0,5 (±0,25 on request) | ±0,5 (±0,25 on request) |

| Bulk density (t/m³) | 0,2 -1,6 | 0,5 - 2,0 | 0,7 - 3,5 |

| Material temperature (t/m³) | +80°C (optionally: +170°C) | +80°C (optionally: +170°C) | +80°C (optionally: +170°C) |

| Operation temperature | -35°C bis +45°C | -35°C bis +45°C | -35°C bis +45°C |

| Protection class | IP65, IP68 | IP65, IP68 | IP65, IP68 |