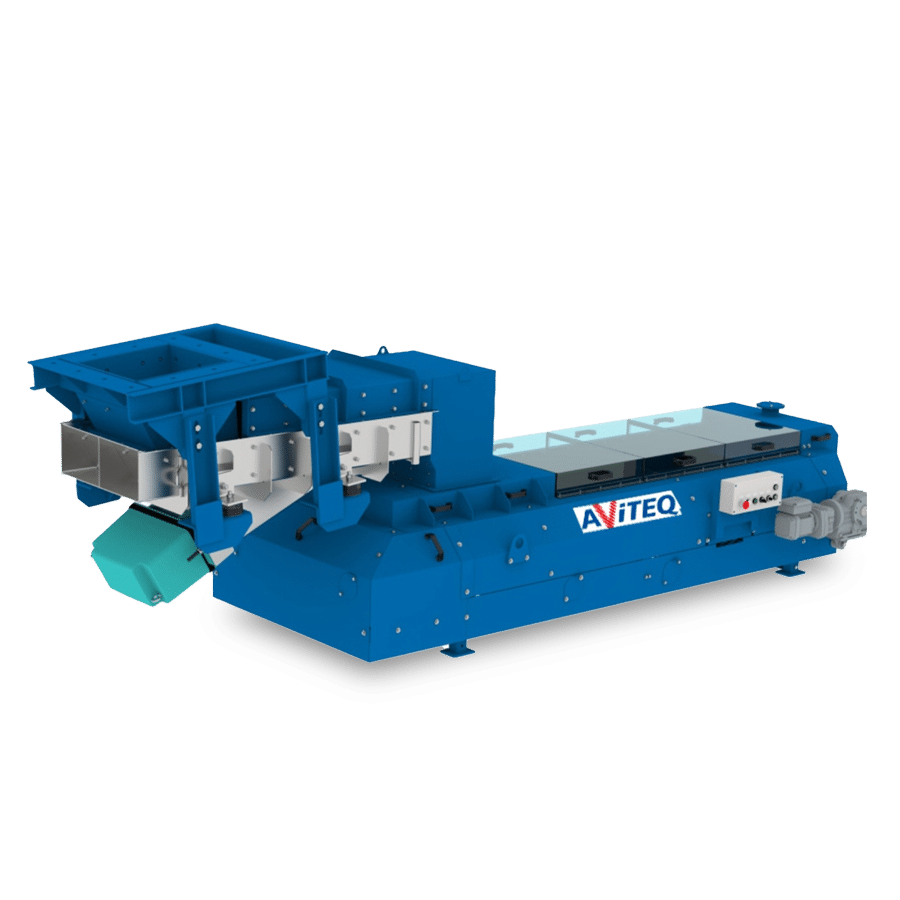

Belt weigh feeders

AViTEQ/Weiteq belt weigh feeders provide high accuracy weighing of a wide range of bulk materials from free-flowing powders to bridging material with coarse pieces and ensure reliable, uninterrupted operation.

At a glance

- AViTEQ/Weiteq belt weigh feeders ensure the precise control of conveying flows for the continuous gravimetric dosing of fine to coarse-grained materials. They are typically used in automated production processes that require continuous weighing and dosing.

- AViTEQ/Weiteq belt weigh feeders can be combined with a wide range of feeders and show their strengths when customized solutions for high weighing accuracy under difficult operating conditions.

are required. Product series are available for a wide range of throughputs. - AViTEQ/Weiteq belt weigh feeders are used wherever precise dosing of main components and additives is required. The belt speed is controlled in such a way that the dosing rate corresponds exactly to the specified exactly to the specified target value depending on the belt load – with a system tolerance of up to ±0.25%.

High accuracy under difficult conditions

AViTEQ/Weiteq belt weigh feeders have been developed for weighing, recording, controlling and dosing bulk materials that are easy to flow and convey and do not cake, even in large mass flows. Depending on the design, our systems can achieve conveying capacities of 30 to 1,500 t/h. They are used in a wide range of industries from luxury food processing to the steel industry. Even under difficult operating conditions, our weighfeeders stand for high long-term and short-term weighing accuracy and reliable, uninterrupted operation.

- Gravimetric measurement

- High throughput of up to 1,500 t/h

- Robust construction

- Use under difficult conditions

- High long-term and short-term accuracy

- Precise dosing

- Simple installation

- Easy belt change

| Technical data | WBF-L | WBF-M | WBF-H |

|---|---|---|---|

| Belt width (mm) | 300 – 1.000 | 800 – 1.400 | 1.200 – 2.000 |

| Center distance drum (mm) | 1.300 – 8.000 | 1.500 – 8.000 | 2.500 – 10.000 |

| max. delivery rate (t/h) | ≤ 50 | ≤ 400 | ≤ 1,500 |

| Control range | 1:10 / 1:20 / 1:50 | 1:10 / 1:20 / 1:50 | 1:10 / 1:20 / 1:50 |

| System tolerance on actual value (%) | ±0.5 (±0.25 on spec. requirement) | ±0.5 (±0.25 on spec. requirement) | ±0.5 (±0.25 on spec. requirement) |

| Bulk density (t/m³) | 0,2 -1,6 | 0,5 – 3,5 | 0,7 – 3,5 |

| Max. Material temperature | +80°C (optional: +170°C) | +80°C (optional: +170°C) | +80°C (optional: +170°C) |

| Ambient temperature | -35°C to +45°C | -35°C to +45°C | -35°C to +45°C |

| Protection class | IP65, IP68 | IP65, IP68 | IP65, IP68 |

Further information

| Brochure Weiteq belt weigh feeders | DOWNLOAD |

Weighing

Discover all products in the “Cradles” range.