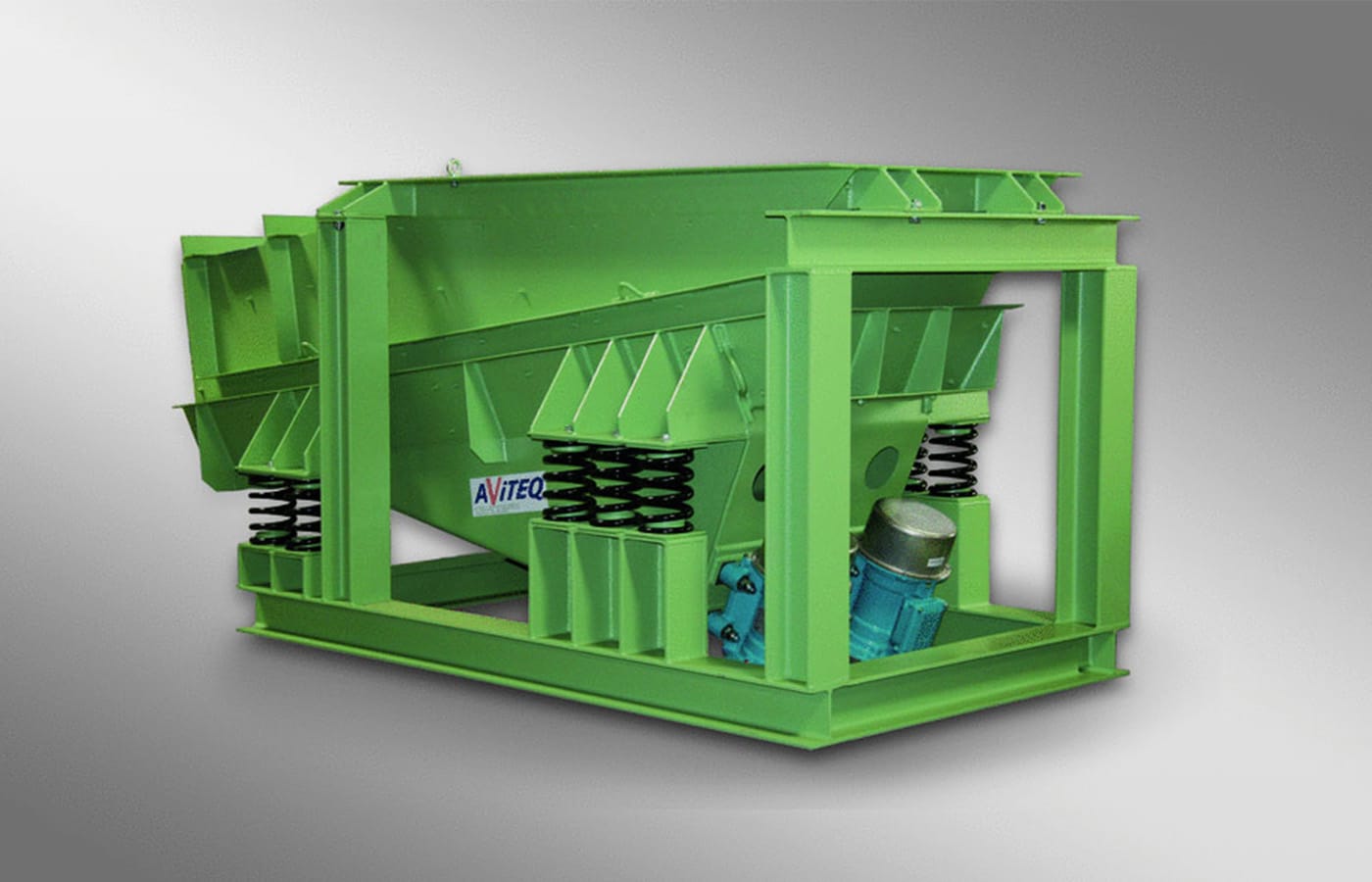

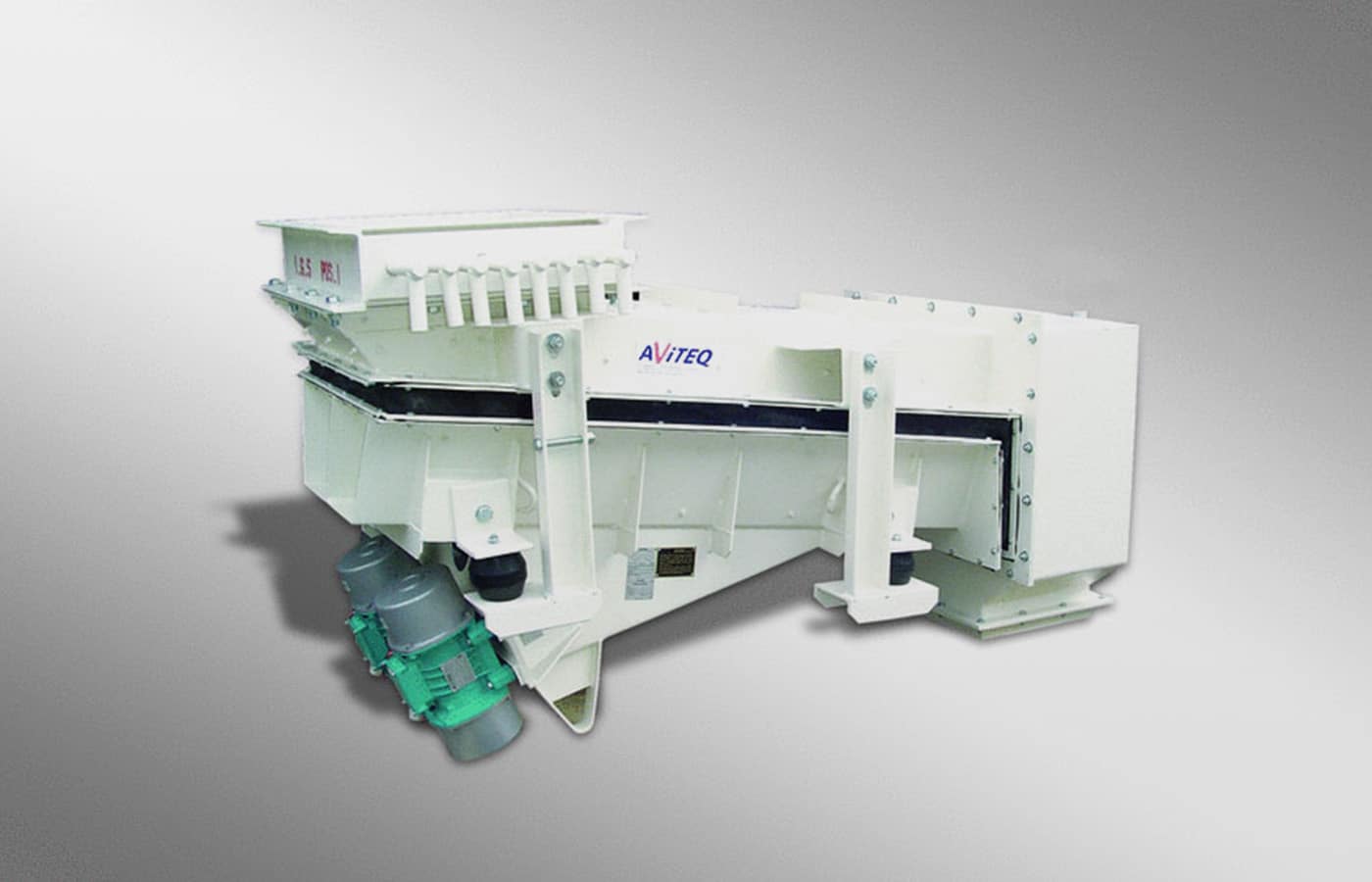

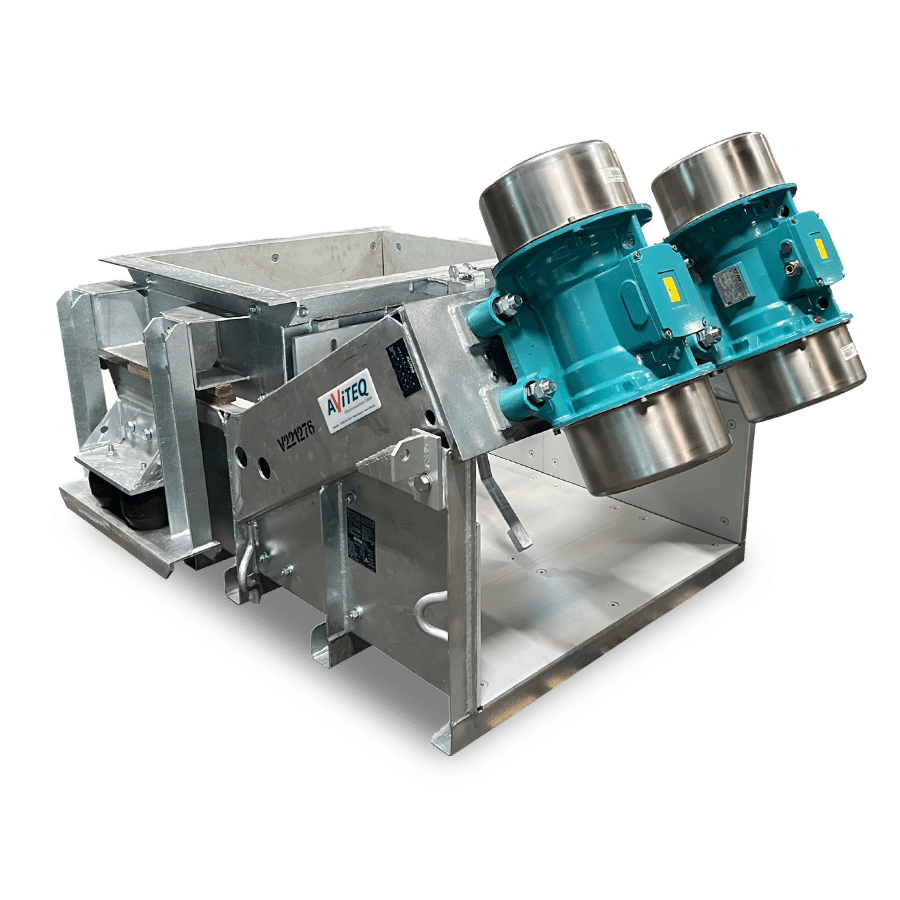

Reliable hopper discharge units

Consistent, safe and blockage-free conveying and bulk material technology requires reliable material feeding and dosing technology. A hopper discharge unit from AViTEQ guarantees uninterrupted production processes in various industries.

At a glance

- Length: Adapt the length of the hopper discharge to your ideas and industry requirements, while at the same time making full and efficient use of the available space. In this way, you maximize the capacity and potential of the system and optimize your throughput capacity.

- Width: With us, you will find a hopper discharge unit that is guaranteed to fit into your working environment and is neither too narrow nor too wide for your purposes and material requirements. This means you avoid blockages when transporting coarse-grained materials and inefficient transportation of fine-grained bulk material.

- Throughput: Whether you are optimizing production capacity, aiming for just-in-time production or other operational goals, we can provide you with a hopper discharge unit with a throughput that will help you increase efficiency, avoid bottlenecks, utilize production facilities and implement all your plans.

High-performance production with AViTEQ hopper discharge unit

Our robust hopper discharge unit serves as a combined capping, discharge, transport and dosing unit and ensures uninterrupted material conveying from the deposit and thus continuous production processes without costly downtimes. The infinitely variable dosing of the magnetic vibrator enables a precise and flexible material flow that can be optimally adapted to your requirements. You always feed the right amount of material into the work process at the perfect time, while avoiding blockages in the hopper discharge unit and connection systems and ensuring energy and operational efficiency as well as the highest product quality.

- Uninterrupted material removal

- Continuous processes

- Infinitely variable dosing with magnetic vibrator

- Maximum energy and operating efficiency

- Immediate stop of the material flow

- Central suspension for high stability

- Dust-tight design for environmental and health protection

Smooth trigger with AViTEQ hopper discharge unit

We rely on quality workmanship and precision when constructing the hopper discharge unit. The robust vibrating feeder meets the requirements of every material and every working environment. The hopper shoe acts as a product guide at the lower end of the vibrating feeder chute to ensure controlled bulk material distribution and guidance. Elastic support elements absorb shocks and vibrations that can cause an uneven material flow and extend the service life of the system. The optional seals prevent the escape of bulk material dust for the sake of the environment and health.

-

High-quality construction

-

Resistant vibrating feeder

- Hopper shoe for controlled bulk material distribution

- Shock-absorbing, elastic support elements

- Seals to prevent bulk material dust from escaping

- Needle or flat slide for immediate closure of the hopper in emergency situations or during maintenance work

Consistently reliable feeding

Discover all products in the “Feeding” area.

下载中心

我们的产品手册及其他资料均提供PDF格式下载。操作指南可根据需求提供。