Linear scale

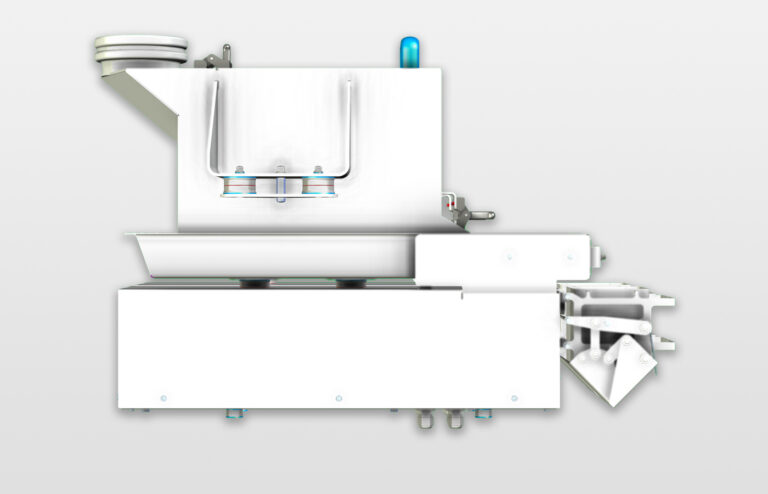

AViTEQ linear scales are used for volumetric or gravimetric dosing of bulk materials. Our systems precisely record the weight per lane and control the material feed via one or more weighing units for exact and consistent product dosing. Ideally suited to the packaging industry.

At a glance

- Precise dosing: The AViTEQ linear weigher is a modular dosing and weighing system for free-flowing products such as nuts, granulates, frozen vegetables or confectionery. The material is dosed into weighing hoppers in a controlled manner via vibrating chutes.

- High accuracy: Thanks to the combination of coarse dosing and fine dosing, the linear scale achieves very high measuring accuracy – even at high throughput rates.

- Wide range of applications: Food industry, chemicals, pet food and non-food products.

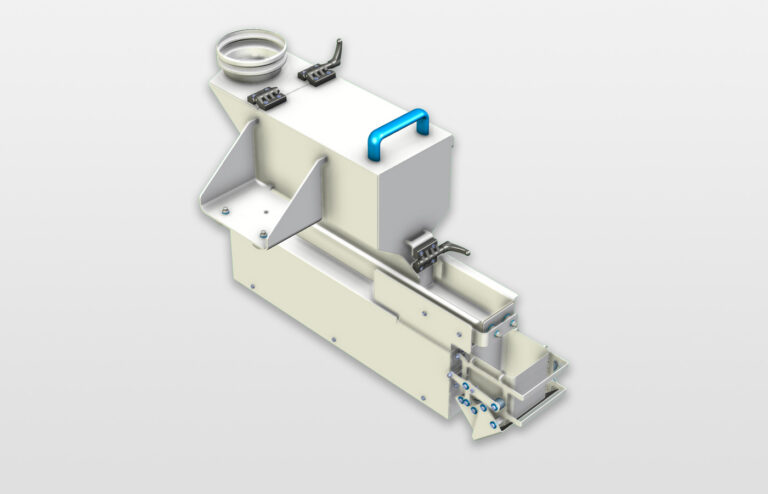

- Fastest disassembly: Thanks to a well thought-out concept, the main components of the weighing hopper, conveyor trough and hopper can be removed as quickly as possible for cleaning.

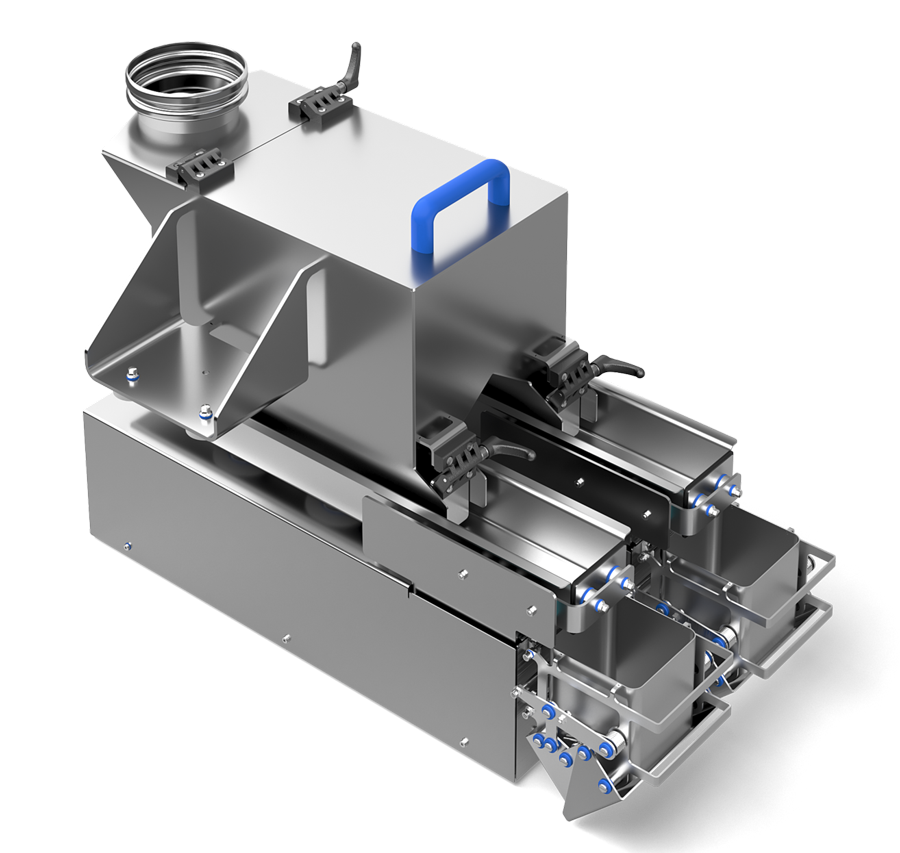

Dosing and weighing in one system – linear scales

The AViTEQ linear scale for the food industry is a precise dosing and weighing system for free-flowing products. It is used in the food, chemical and pet food industries as well as for non-food applications. As a dosing weigher for granulates, nuts, frozen vegetables or confectionery, it combines the functions of dosing and weighing in one compact device. The bulk material is fed into the weighing hopper in a controlled manner via multi-track vibrating chutes, where coarse dosing and fine dosing achieve a very high level of accuracy combined with high performance. In addition to precise weighing, the linear weigher also enables the continuous feeding of packaging and processing lines. The wide range of applications of the AViTEQ linear scale at a glance:

- Precise dosing and weighing of e.g. nuts, granulates, frozen vegetables, confectionery and much more

- Linear weighfeeder for filling in packaging and filling systems

- Portioning of small and medium-sized batches (from 10 g) with high accuracy

- Consistent product feed for mixing and filling processes

- Flexible adaptation to different product types and hygiene requirements

- Magnetically held main components for quick removal and cleaning

Modular design – can be flexibly combined

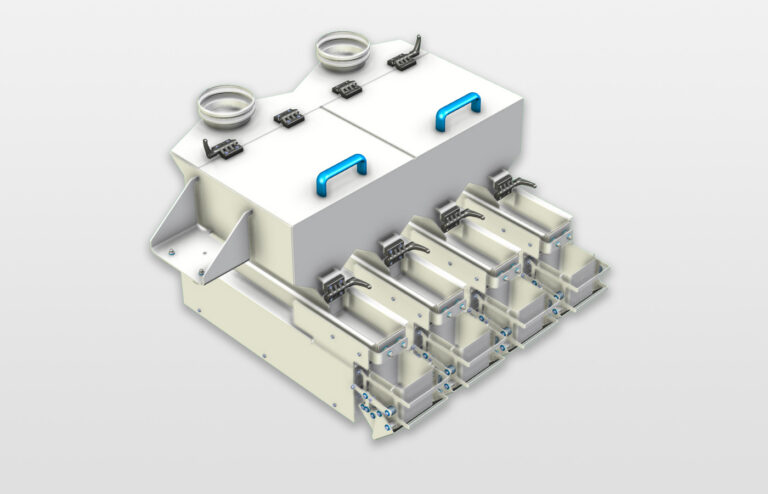

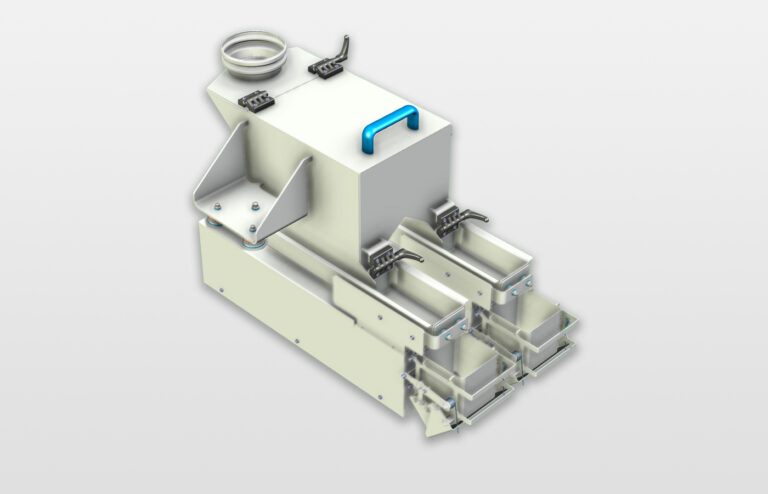

The linear weigher consists of several small conveyors (vibratory feeders) that feed the product evenly and gently into the weighing containers. Thanks to its modular design, the system can be expanded, adapted and easily cleaned – perfect for varying product types and hygiene standards.

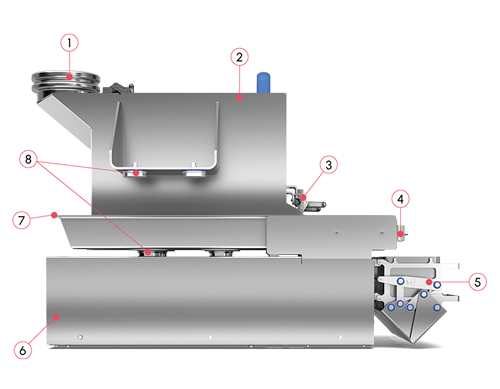

Overview of the main components:

- Small conveyors / vibrating feeders (also in V2A) for fast and precise dosing

- Hopper with optional precise fill level sensor and slider at the outlet for fine adjustment

- Weighing container can be removed without tools

- Touch HMI control for operating and monitoring the linear scale

- Custom configurations can be made based on product characteristics and hygiene requirements

- Robust frame construction for continuous operation

- Inlet variants: open, with sleeve and clamping profile or with BFM nozzle

- Hopper variants (25 l or more): open or closed with flap (optionally with inspection

- Layer height slider with quick lock for precise fine adjustment of the material flow

- Automatic slider enables fast closing and increases weighing accuracy

- Weigh hopper can be removed without tools for quick and easy cleaning

- Dosing drive (optionally made of stainless steel) various oscillation frequencies,Magnetic system IP65 and KTL-coated

- Smooth dosing chutes or with textured plate, magnetically held for quick change

- Magnetic holder for quick change of hopper and trough

Materials

- Metal: stainless steel 1.4301 (AISI 304)

- Metal surface treatment: electrochemically polished or blasted

- Plastics: FDA-approved

| Technical data | Specification | Note |

|---|---|---|

| Number of tracks / channels | 1-lane, 2-lane, 4-lane | Influences throughput and flexibility with product variety |

| Max. Weighing quantity | 10 g – 5 kg per channel | Auch Ausführungen für Kleinmengen <10 g verfügbar |

| Weighing range / resolution | 0.1 g – 5 kg with 0.1 g resolution | Fine-resolution load cells for precise dosing |

| Max. Power / number of cycles | Up to 20 weighings / minute per track 1 | 100 – 10,000, more on request |

| Accuracy / Tolerance | ±0.2 g for standard product | Depending on bulk material (density, pourability) |

| Hopper volume, details | 25 l per lane or more, with layer height slider, held magnetically, can be removed without tools | Determines refill intervals and buffering Optional: with fill level sensor |

| Materials / Hygiene | Stainless steel 1.4301 2, food-safe, CIP, IP65/IP69K optional | FDA-compliant plastic parts, hygienic design |

| Vibration frequency | 25-100Hz可调 3 | Adaptable to bulk and piece goods, high flexibility |

| Power supply | 230 V, 50/60 Hz | Standard mains connection |

| Gutter details / Trough system | pickled and passivated, held magnetically, can be removed without tools | Quick cleaning and trough change Optional: Electropolished, ViwateQ |

| Weighing hopper details | pickled and passivated, removable without tools | Quick cleaning Optional: Electropolished, ViwateQ |

| Operation / Interfaces | 7″ touchscreen, PLC connection, Ethernet/IP | Simple line integration, user-friendly |

2 optionally in 1.4401 or 1.4571

3 at 50 Hz mains frequency

Special versions on request

Individually designed – for your application

Every AViTEQ linear scale is developedto meet the customer’s requirements.Important parameters for the design are

- Type and size of the conveyed goods

- Desired accuracy and dosing characteristics

- Throughput quantity per hour

- Integration into existing packaging or production lines

- Custom configurations can be made based on product characteristics and hygiene requirements

- Spatial conditions and installation dimensions

The result is an efficient and reliable solution that fits your production perfectly.

FURTHER INFORMATION

| Flyer linear scale | DOWNLOAD |

Weighing

Discover all products in the “Weighing / weighing” range.