Vibrating table

The AViTEQ vibrating tables master two tasks at once: On the one hand, they efficiently compact bulk materials such as concrete mixes and, on the other hand, they are able to reliably knock out or loosen molds.

At a glance

- Compacting and loosening: The AViTEQ vibrating table is designed for compacting and loosening bulk material. This makes the table ideal for emptying containers using periodic impacts and for cleanly knocking out molds. Concrete mixtures can also be compacted efficiently.

- For high payloads: The load capacity of the vibrating table can be flexibly adapted to the application. Thanks to the robust and stable design, payloads of up to 3,000 kg can be accommodated.

- Good dosing capability: Depending on the application, the vibration properties need to be precisely dosed. Our infinitely variable magnetic vibrators, which are also considered to be particularly reliable and wear-free, are suitable for such cases.

AViTEQ Vibrating tables: Versatile, compact, adjustable

The AViTEQ vibrating tables master two tasks at once: On the one hand, they efficiently compact bulk materials such as concrete mixes and, on the other hand, they are able to reliably knock out or loosen molds.

- Versatile use: compacting and loosening

- Precise dosing of the vibration using magnetic vibrators

- Compact design

- Up to 3,000 kg payload

- Up to 4,000 mm long and 2,000 mm wide

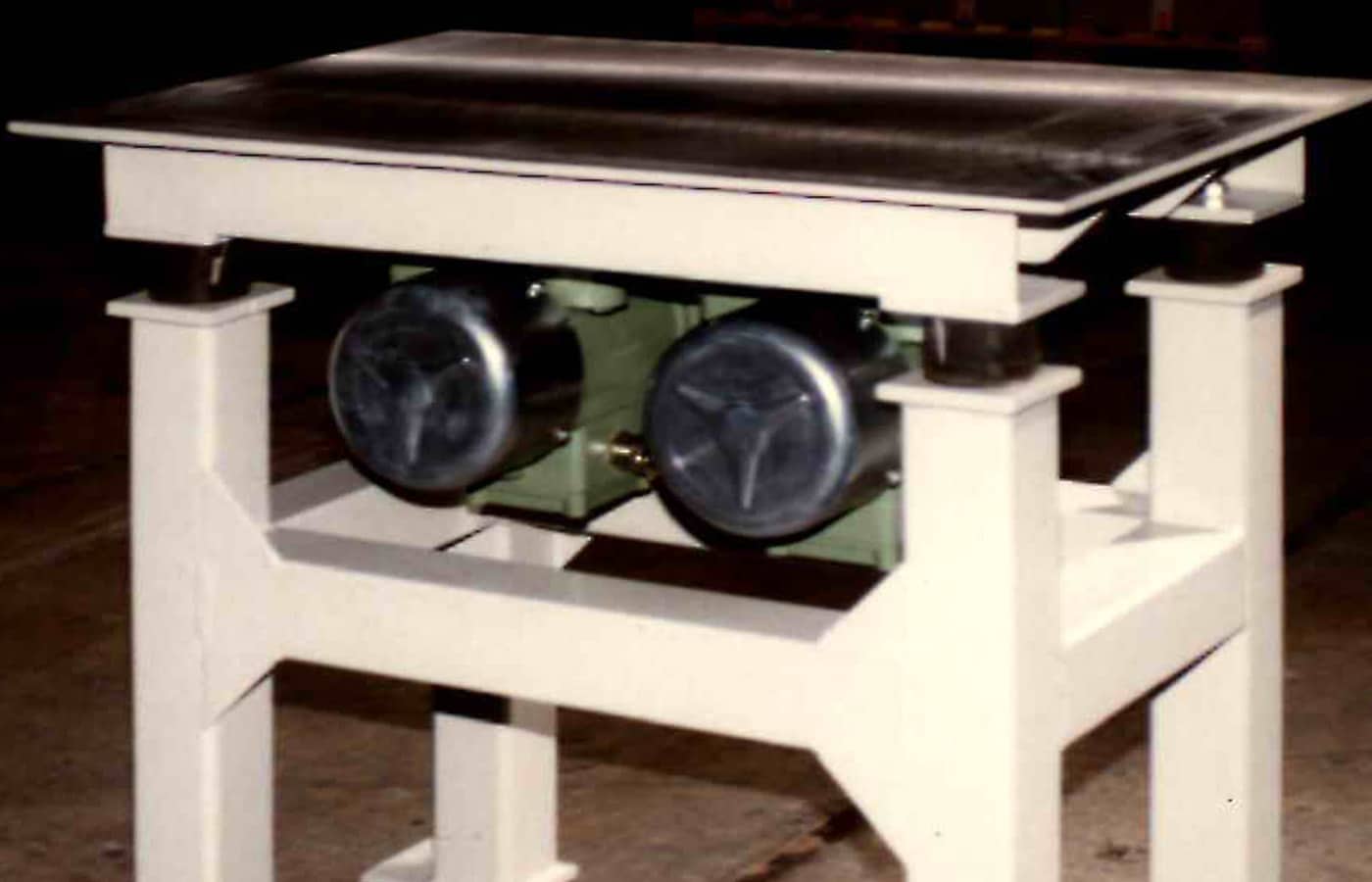

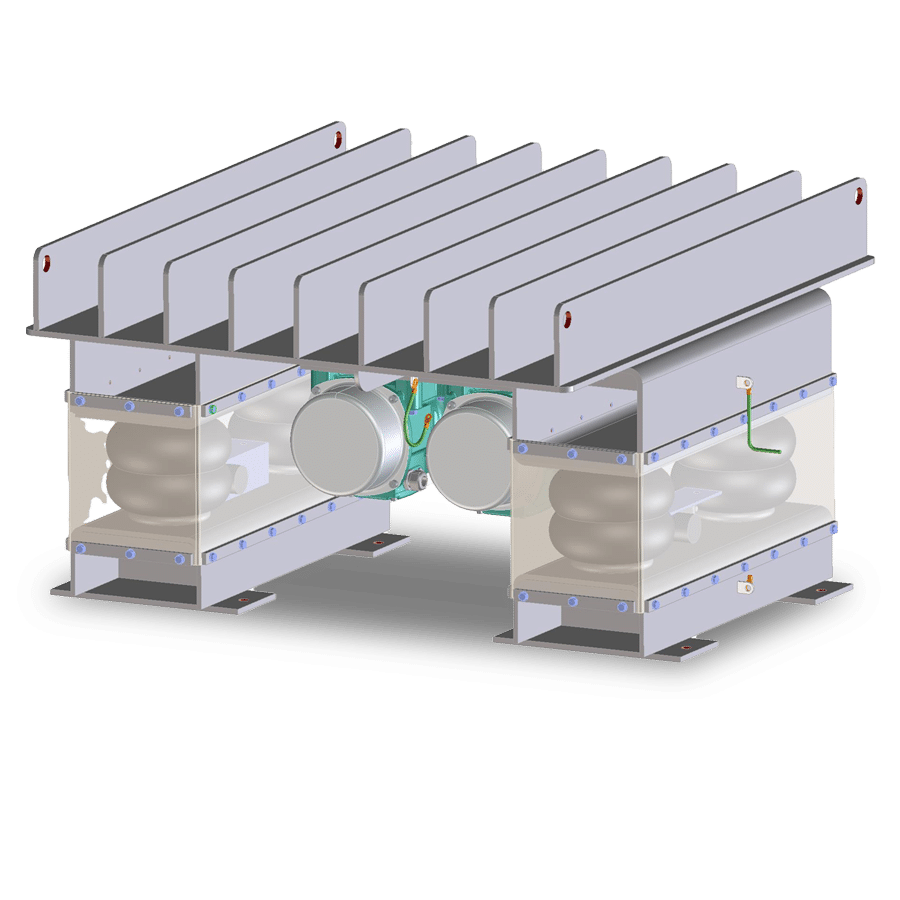

Compact and robust design

The structure of the AViTEQ vibrating table can be flexibly adapted to the type and size of the bulk material. The high-quality construction with durable materials ensures a stable stand and safe, robust operation. The drive technology is integrated under the table top, ensuring a compact design and direct power transmission. The resulting vibration forces can be reliably absorbed by damping devices.

- Compact and robust design

- Lengths up to 4,000 mm

- Widths up to 2,000 mm

- Payloads up to 3,000 kg

Customized design for your application

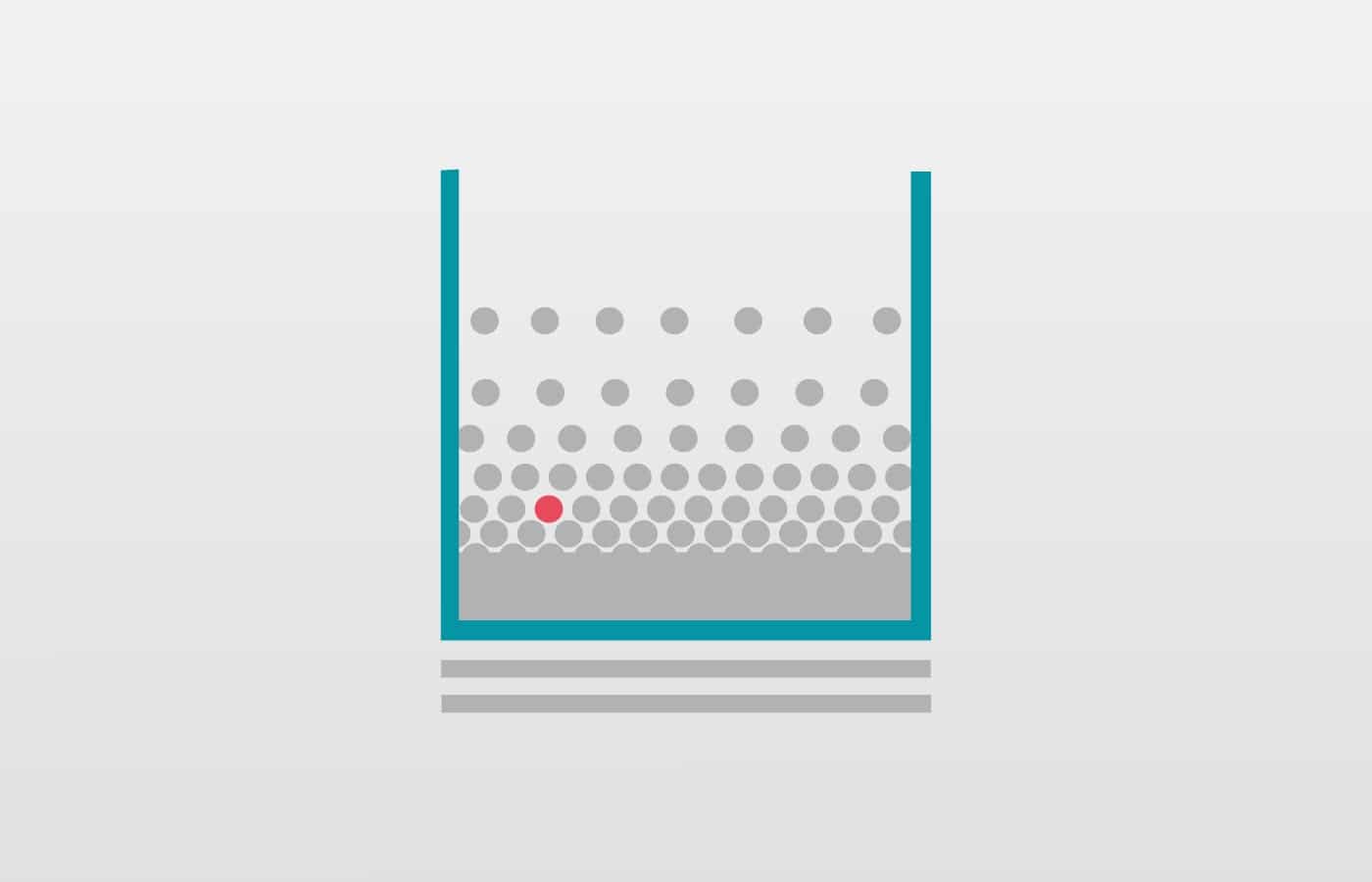

Our vibrating tables are dimensioned according to individual requirements. The properties of the bulk material are particularly important here: bulk weight, volume, grain shape and internal friction all have an influence on the design of the vibrating table. In addition, the intended bulk material container with its relevant properties such as dimensions, rigidity and sidewall friction also play a role in the dimensioning. The dimensioning depends on:

- Bulk material (bulk density, volume, grain shape and internal friction)

- Bulk container (height, rigidity and side wall friction)

- Application (compacting, loosening, knocking out)

Drive types for vibrating tables

Unbalance motor

Find out more about our unbalance motors here

Magnetic vibrator

Find out more about our magnetic vibrators here

Compacting

Discover all products in the “Compacting” range.

下载中心

我们的产品手册及其他资料均提供PDF格式下载。操作指南可根据需求提供。