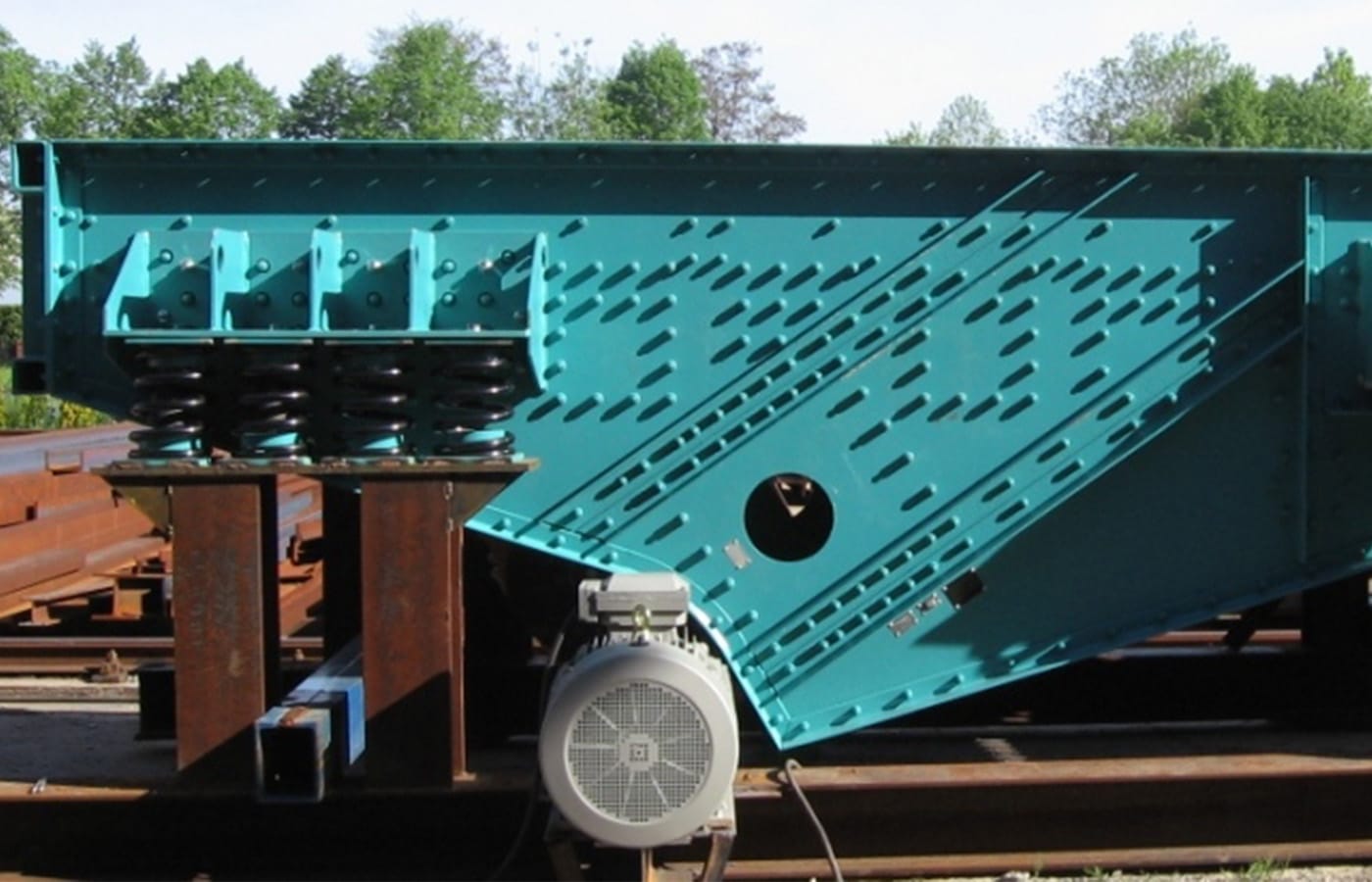

Bar screen

The AViTEQ GRIZZLY bar screen belongs to the bar screen class and shows its strengths when conveying and prescreening coarse grain. The robust screen scores with a wide range of applications, high operational reliability and high throughput rates.

At a glance

-

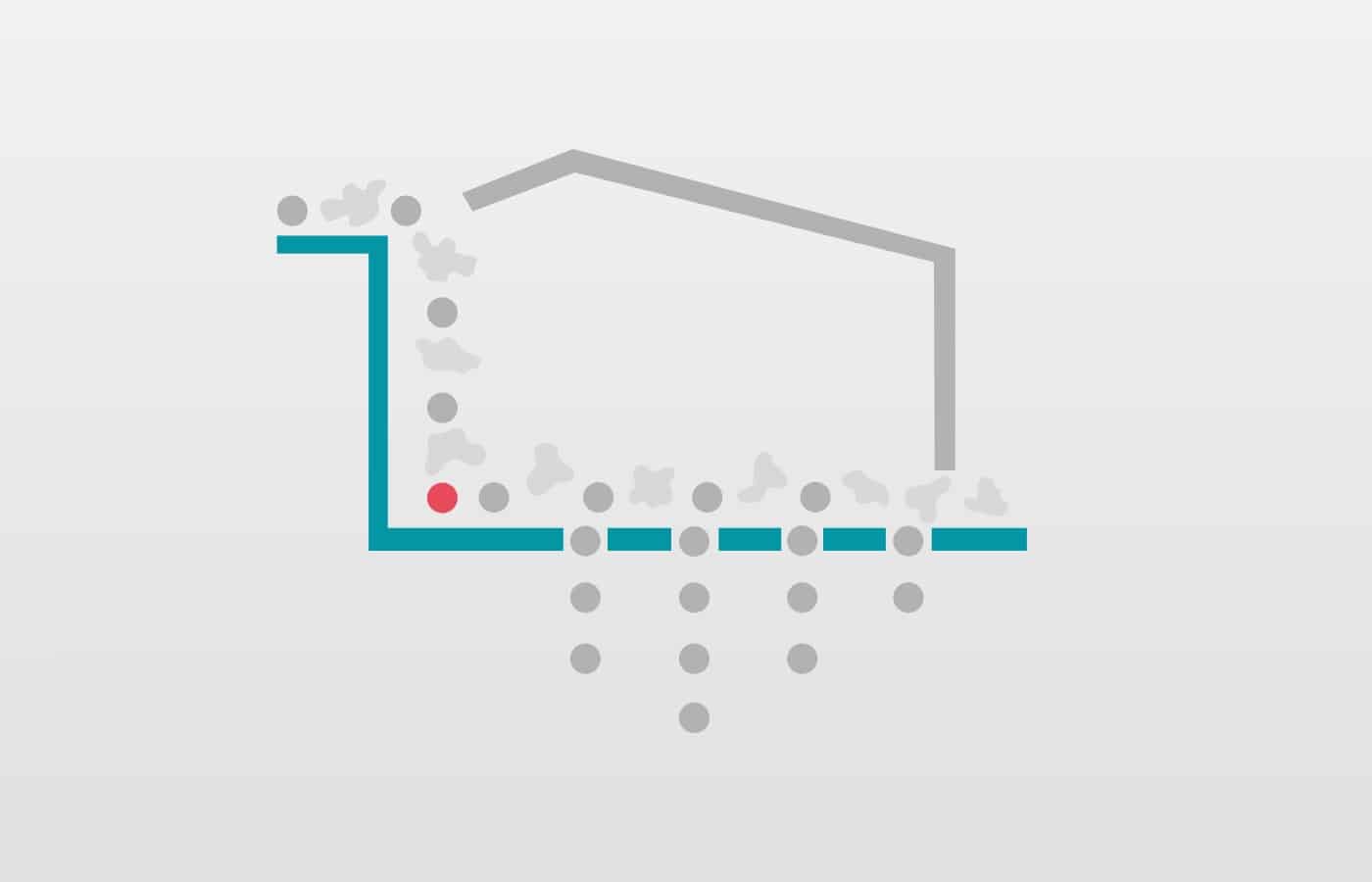

Wide range of applications: The bar screen fulfills several tasks at the interface between the silo and downstream processing systems. It enables the controlled discharge of bulk material and at the same time pre-screens large grain sizes. The coarse material is then fed to the crusher, screener or conveyor belt.

- Tapered bars: For the longest possible service life and best productivity, the bars of the bar rack have a tapered profile in the conveying direction. This reliably prevents the bulk material from becoming wedged in the grate.

- High conveying capacity: The bar rack screen can be individually designed for a conveying capacity of up to 1,500 m³/h and thus ensures maximum efficiency and productivity for demanding conveying, screening and feeding tasks.

Robust, durable, versatile

The AViTEQ bar screen is designed for demanding conveying, screening and feeding tasks with heavy coarse grain. The design of the system therefore meets the highest requirements in terms of resistance, robustness and durability. Sturdy wear plates in the inlet area ensure mechanical protection of the bar screen, while elastic support elements reliably absorb the forces acting on them. Up to three bar screen stages with a tapered bar profile ensure efficient and reliable conveying. The bar screen has a wide range of applications:

- Extracting bulk material from bunkers and silos

- Conveying and screening of coarse grain

- Separation of coarse grain before classifying screens

- Separation of fines before crushers

- Protection of conveyor belts by specifying fine grain

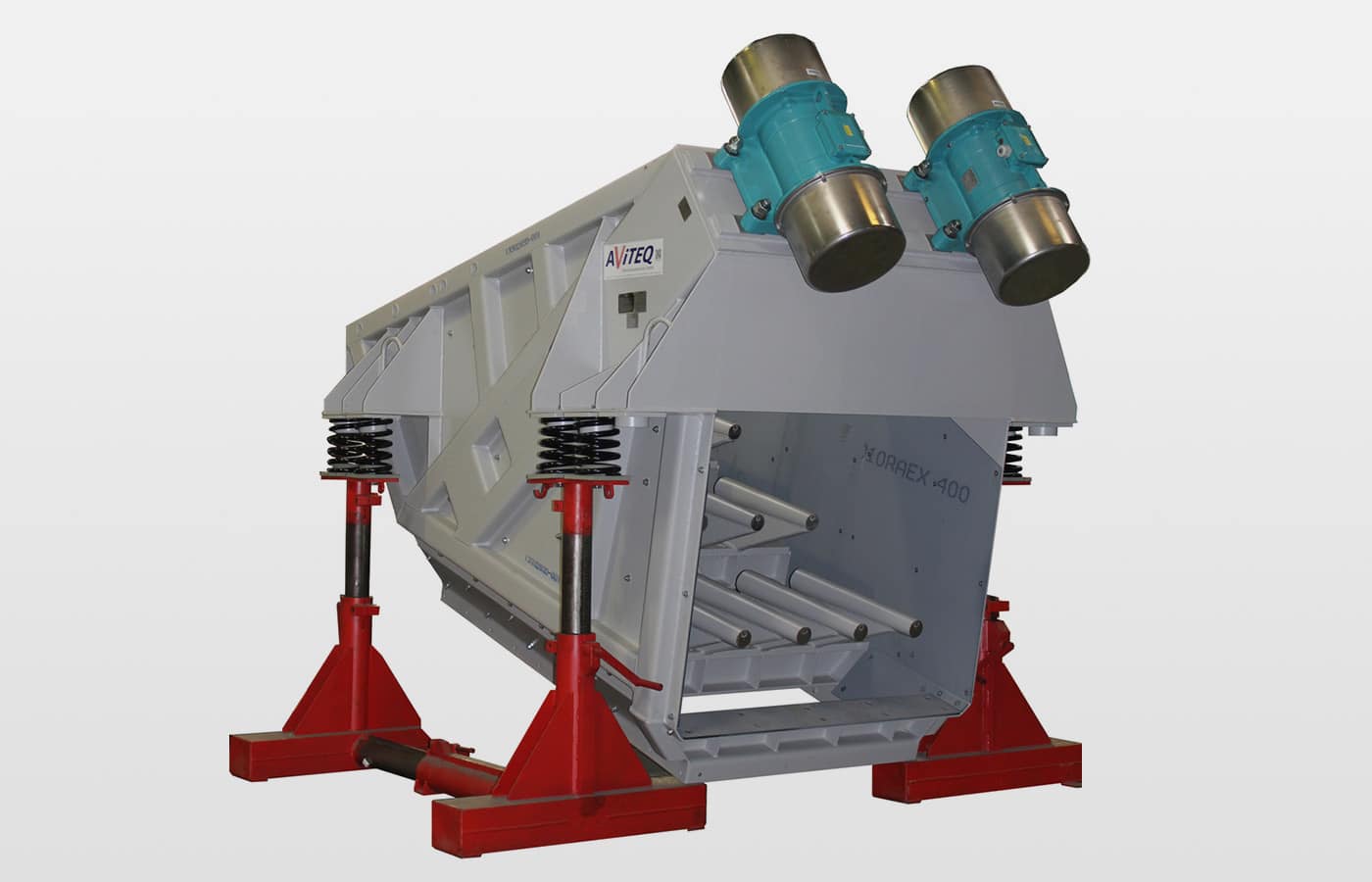

Stable and durable – the structure

The robust design of the AViTEQ bar screens is aimed at durability and low wear. The coarse-grained bulk material falls onto sturdy wear plates in the inlet area and is guided from there over either two or three bar grate stages. Depending on the desired screening effect, the rows of bars integrated in the grate can have variable spacing and ensure separation of fine and coarse particles. While the fine material falls through between the bars, the coarse material is conveyed further above the bars, for example to the crusher or classifying screen. The main components at a glance:

- Conveyor with drive traverse

- Bar grating inserts with tapered profile in the conveying direction

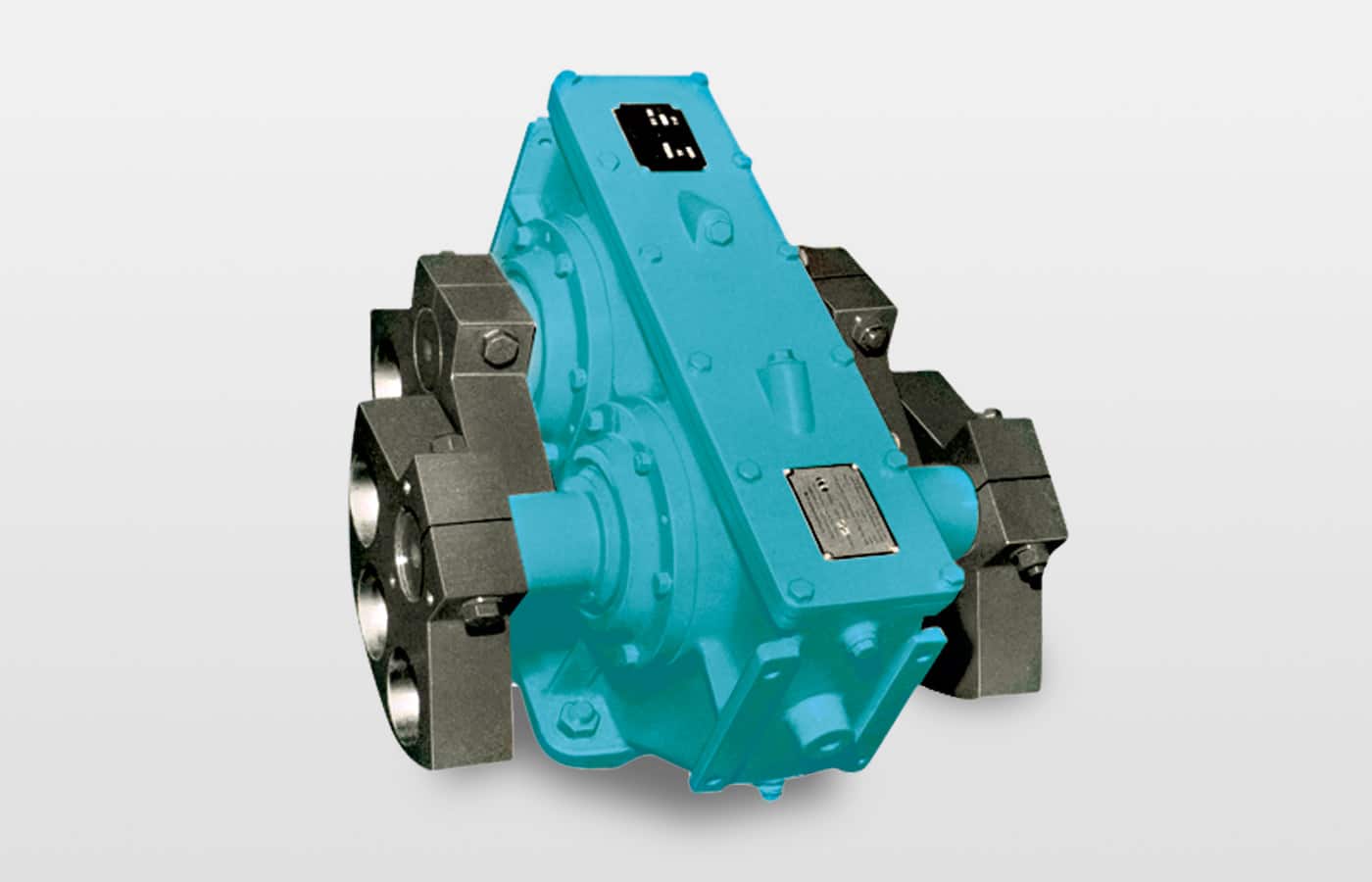

- Powerful drive (unbalance motors / unbalance exciters)

- Elastic support elements for force absorption

Customized bar screen for your application

The design and dimensioning of the AViTEQ GRIZZLY bar screen is tailored to your individual requirements. In addition to the type and size of the material to be conveyed, the throughput volume to be conveyed is also decisive – this can be up to 1,500 m³/h. The design and arrangement of the bar rack depends on the desired separation size. In addition, the space available at the installation site is also taken into account in the individual design of the bar screen.

Here is an overview of the most important parameters for dimensioning:

- Conveyed goods (type and size)

- Conveyed volume

- Throughput quantity

- Separation size

- Possible installation dimensions

Drive types for bar screens

Unbalance exciter

Find out more about our unbalance exciters here

Unbalance motor

Find out more about our unbalance motors here

Protective and control screening

Discover all products in the “Protective and control screening” range.

下载中心

我们的产品手册及其他资料均提供PDF格式下载。操作指南可根据需求提供。