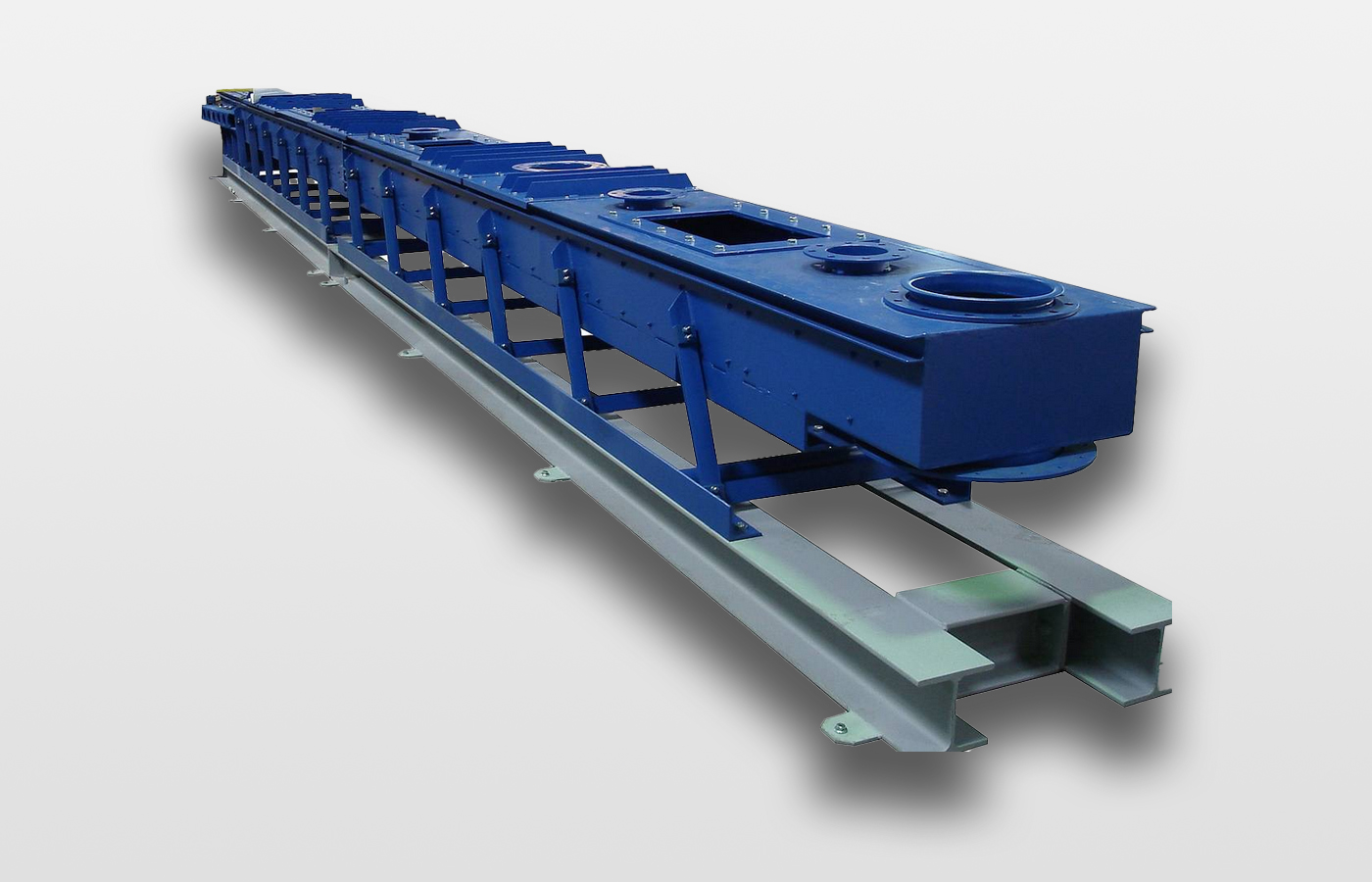

Guide arm long trough conveyor

Our guide arm long trough conveyors ensure the safe removal of sharp or hot waste materials in industrial processes. These compact flatbed conveyor troughs are low-maintenance, gentle on materials and reliable in operation.

At a glance

- Ideal force absorption: An ingenious design connects the conveyor trough via a guide arm to a vibration-reducing reverse pendulum on compression springs, ensuring optimal force absorption. Up to 99% of dynamic forces are isolated and cannot be transmitted to the surroundings.

- Space-saving construction: Thanks to intelligent force isolation technology, the trough structure of the conveyor and its base can be kept small, resulting in a very low overall machine height. This space-optimized design allows the conveyor system to be more seamlessly integrated into your production process.

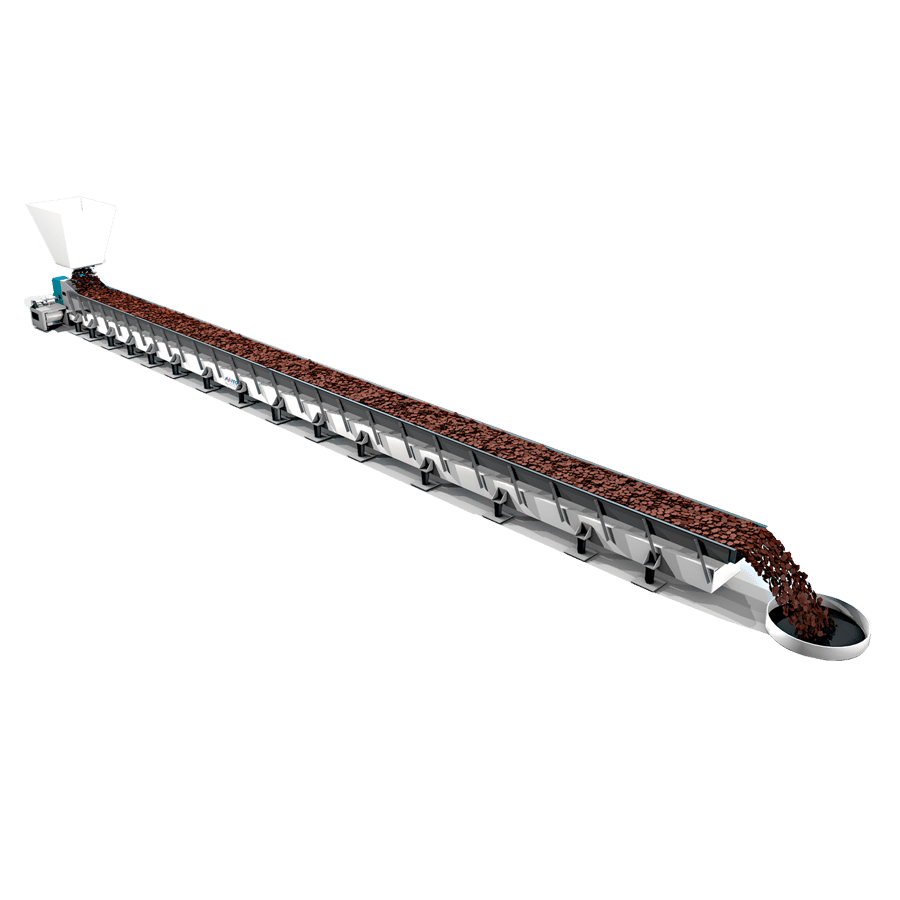

- Gentle Material Conveying: Waste materials from manufacturing processes are often returned to another part of the production line or used for other purposes. Our flat design vibratory conveyor chutes are particularly gentle and friendly to the material.

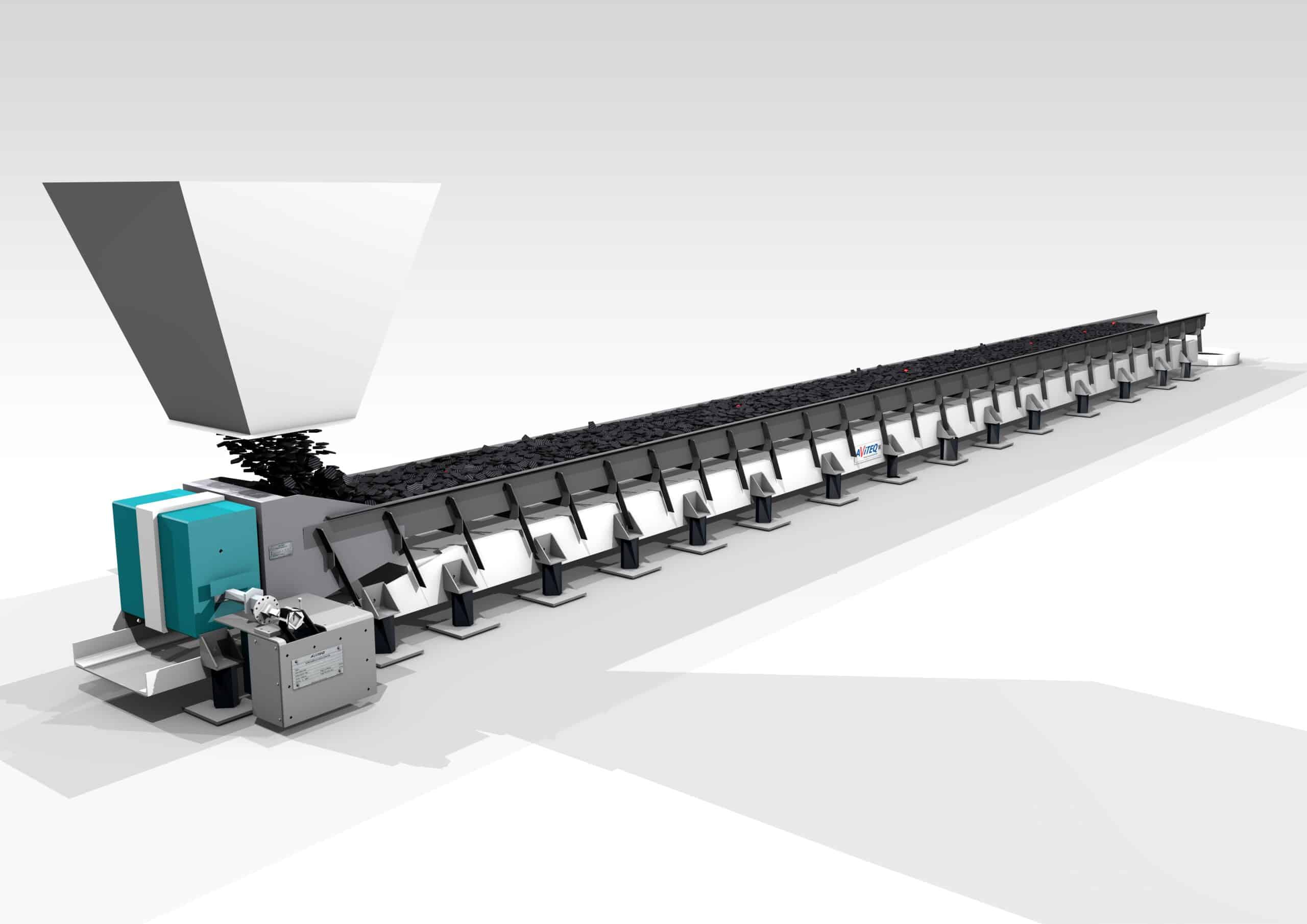

Discharge, feeding and conveying of waste materials

In industrial processes, sharp or hot waste materials are often transported using underground pit solutions. Metal shavings, foundry sand, stamping scrap or other waste materials often need to be transported over long distances before they can be processed. Disadvantages include high maintenance costs, time-consuming trench cleaning and frequent production interruptions. Our guide arm long channel conveyors solve these problems by transporting scrap safely, gently and compactly. In addition, we offer a completely dust-proof design. The advantages of flexible link long conveyors at a glance:

- Low mounting height

- Safe conveying of high temperature and sharp materials

- Material Friendly Conveying Process

- Conveying chutes designed for a maximum length of 22 meters

- Sealed dustproof design

- large capacity

- Low wear and low maintenance

Design: Compact, low maintenance, material friendly

Ingenious solution: Due to the intelligent isolation of dynamic forces, guide arm long trough conveyors can be constructed in a very compact manner. The troughs in the conveyor system are connected by means of a pendulum arm to a reverse pendulum frame equipped with compression springs. This design ensures that up to 99% of the dynamic forces are isolated and that the frame and foundation take up very little space. Depending on the application, trough lengths of up to 22 meters are possible. The main components of the Guide Arm Long Trough Conveyor include:

- Foundations and frameworks

- guide arm

- Shock absorbing reverse pendulum

- Metal Compression Springs

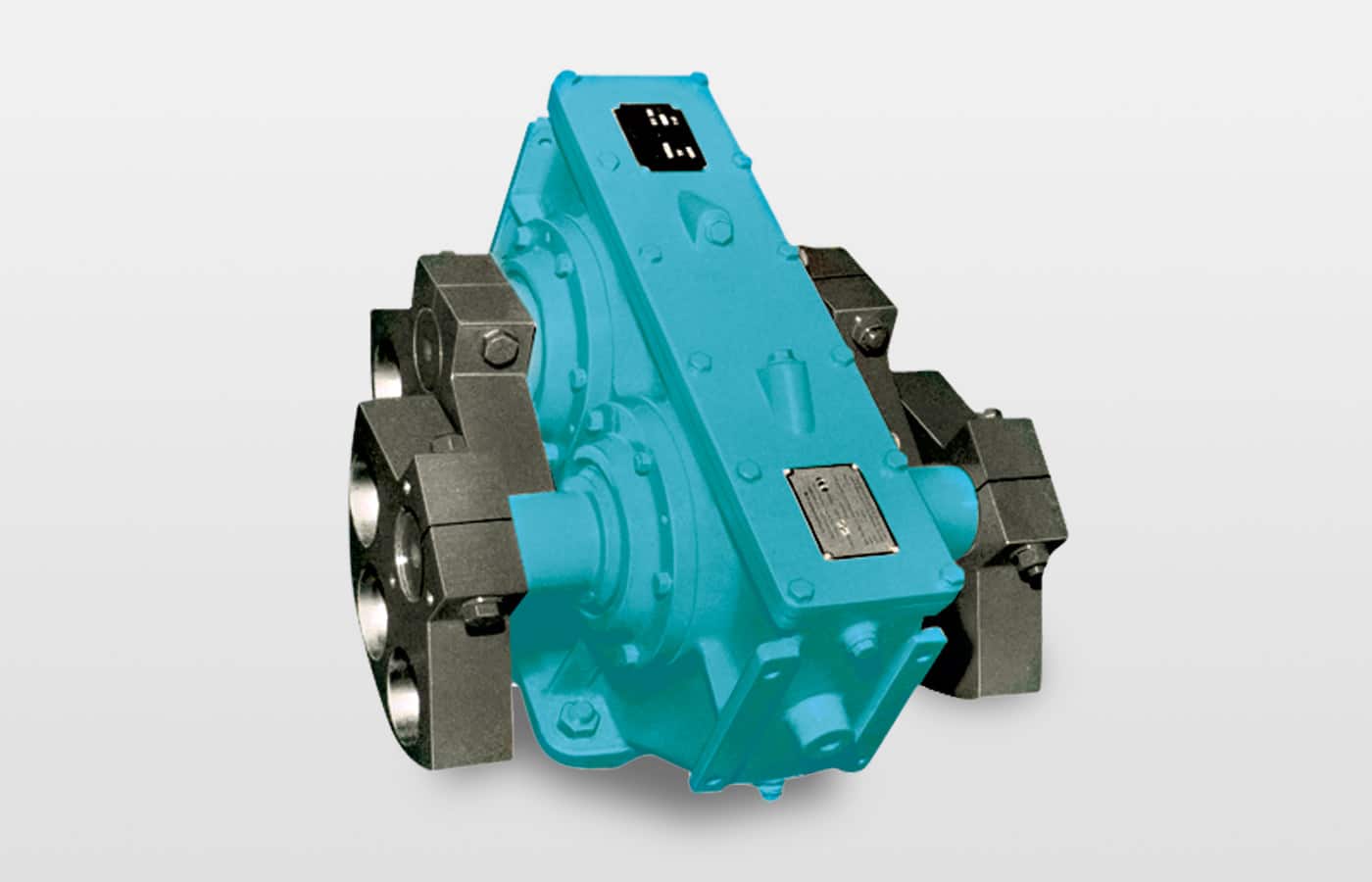

- Vibration drives (vibration motors, eccentric shakers, crank-slider mechanisms)

- large capacity

- Slot lengths up to 22 meters, widths up to 900 mm

Individualized design according to your production process

Industrial production processes vary. That’s why we design our guide arm long trough conveyors with the goal of meeting your specific production needs. We start by analyzing the type of waste material, whether it is sharp metal shavings or high-temperature foundry sand. Depending on the material to be conveyed, we use different conveyor body materials. The external dimensions of the conveying solution depend primarily on the volume of material to be conveyed and the spatial conditions, i.e. the conveying distance. We can realize conveying distances of up to 22 meters and conveying capacities of up to 180 cubic meters per hour. The sizing of the equipment depends on:

- Types and characteristics of materials to be conveyed

- Required conveying capacity

- Material Size

- Pit height

- Sealed dustproof design

- Conveying distance

Drive types for link-guided conveyor troughs

Unbalance motor

Find out more about our unbalance motors here

Unbalance exciter

Click here to learn more about our Eccentric Shakers.

Horizontal conveying

Discover all the products in the “Horizontal Vibratory Conveying” range.

下载中心

我们的产品手册及其他资料均提供PDF格式下载。操作指南可根据需求提供。