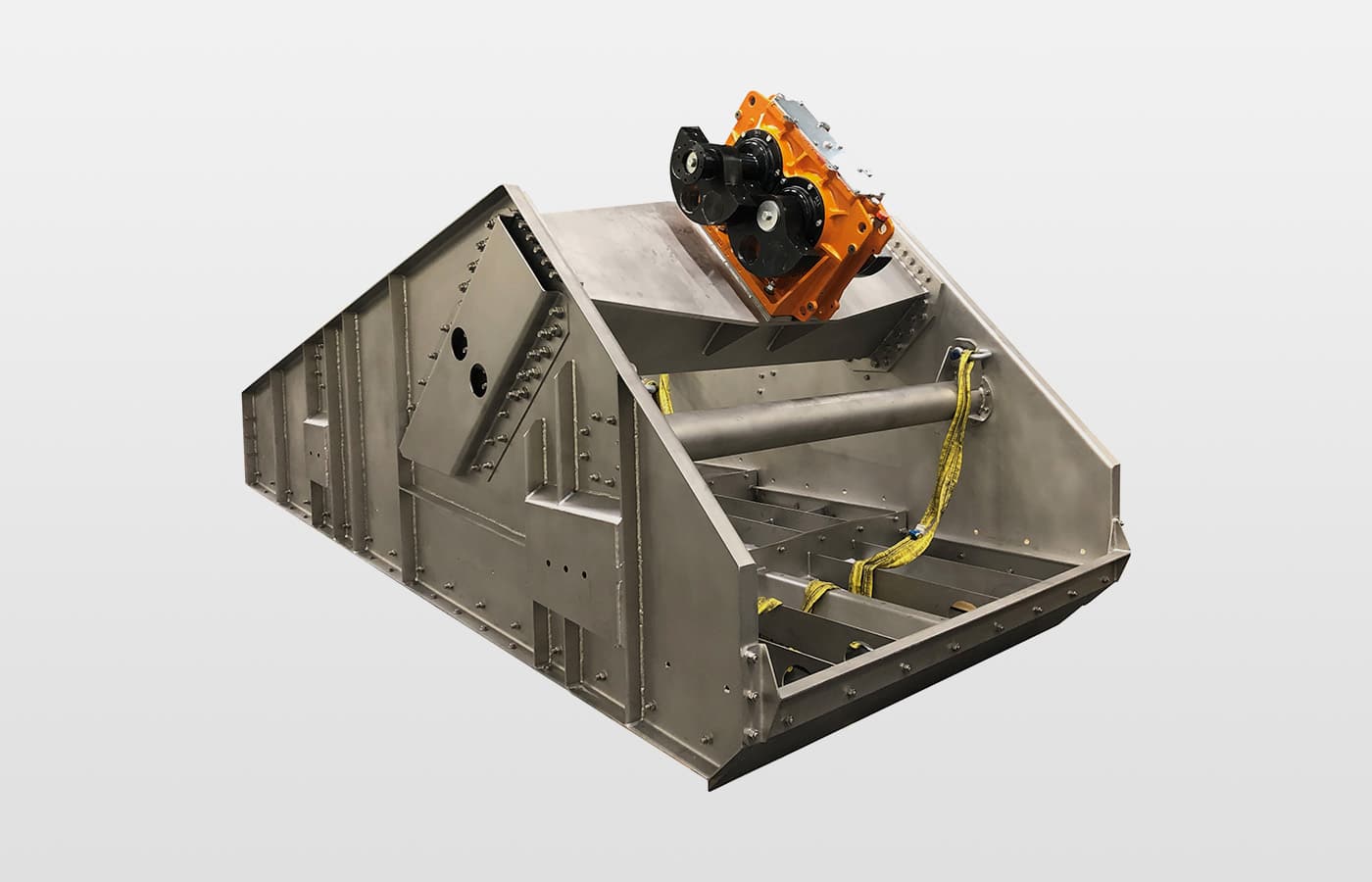

Strong Unbalance exciter

The powerful AViTEQ unbalance exciter is suitable for application scenarios requiring high torque. This linear vibrator operates smoothly, enabling continuous operation even at the 100% centrifugal force setting, while featuring low noise and low maintenance costs.

Powerful drive, suitable for long-term operation

Our unbalance exciters demonstrate their advantages in long-distance material conveying requiring high operating torque. These driving devices feature outstanding performance, high cost-effectiveness, and extremely stable operation. AViTEQ unbalance exciters are designed for continuous operation at the 100% centrifugal force setting. With a rated power of up to 90 kW and a maximum effective load of 20 tons, they are suitable for medium-sized and extra-large vibrating machinery. If higher operating torque is required, multiple eccentric vibration exciters can be connected in series arbitrarily.

- Powerful drive, high output torque

- Modular coupling enables higher torque

- Stable and continuous operation at 100% centrifugal force

- Durable and sturdy

- Low-noise operation

- Low maintenance requirement

- Static Torque: 4,130 to 73,440 kg/mm

- Maximum Centrifugal Force: 453 kN

Robust and shock-resistant cast housing

AViTEQ unbalance exciters boast an extra-long service life, thanks to their robust and wear-resistant design as well as the shock-resistant cast housing. At the core of the driving device are two rotating shafts; at each end of the shafts, highly synchronized eccentric wheels are installed, which rotate in opposite directions to generate combined linear vibration. The external drive unit can be connected to 50 Hz or 60 Hz three-phase current as needed, and is compatible with all standard voltages up to 690 V. This drive unit offers optional protection class IP66 (in compliance with DIN EN 60529 standard) or ATEX explosion-proof rating. Additional counterweights can be mounted on the eccentric wheels of the vibration exciter to adjust the static torque.

-

Shock-resistant cast housing

-

The synchronization of the eccentric wheels is achieved through two sets of gears

-

The rotating shaft is mounted in four wear-resistant spherical roller bearings

-

Forced synchronous counter-rotating eccentric flywheels

-

Adjust the static torque by installing additional counterweights.

-

Optional: Traction motor with IP66 (per DIN EN 60529) or explosion-proof rating compliant with ATEX standards

Further information

| Variants of unbalance exciter | DOWNLOADS |