+86-21 37047777 ext. 0

sales@aviteq.com.cn

Contact

Contact

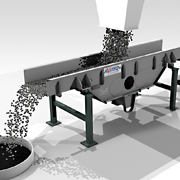

AViTEQ Reversible-feeder is suitable for applications where material needs to be conveyed and dosed in two opposite directions, and can be constructed as a tubular feeder or a trough feeder. AViTEQ bidirectional feeders are commonly found in the food and chemical industries, but are also suitable for industries such as resource recovery and raw material production. When the electromagnetic vibrator is used as the driver, high-precision two-way feeding and start-stop switching function of any frequency can be realized.

Features & Benefits

Construct features

The main components of the bidirectional feeder include:

Design selection

The dimensions of the twin line feeder mainly depend on:

Key figures