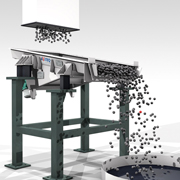

AViTEQ Reversible-troughtubular-feeder is suitable for conveying and metering flow bulk materials of virtually any particle size. Because of its sturdy, open, well-shaped tank structure design, it is especially suitable for use under extreme environmental conditions; At the same time, because of its easy cleaning, it is also widely used in the chemical and food industries.

Features & Benefits

Wide range of applications:

- Electromagnetic vibrator or inertial vibration motor can be used as its driver;

- It can be designed with a closed dust-proof structure;

- It can be used in series connection to achieve longer distance conveying;

- Multiple drives can be driven in parallel;

- The construction material can be carbon steel or stainless steel

Construct features

The trough feeder has a simple structure, and its main components include:

- conveying trough with excitation frame;

- drives mounted on exciters;

- Receiver/discharge port (when the closed structure is designed);

- elastic support components;

- Soft connections

Design selection

Its dimensions mainly depend on:

- the type of material being conveyed;

- conveying volume requirements;

- conveying distance and interface form of upstream and downstream equipment;

- The quality of the installation that the platform can withstand

Key figures

- Length: The maximum length of a single machine is 9 meters, but the total conveying distance is theoretically not limited when connected in series;

- Width: maximum width 3.5 meters;

- Conveying capacity: up to 1000 cubic meters / hour;

- Applicable drivers: electromagnetic vibrators, inertial vibration motors, exciters

...