+86-21 37047777 ext. 0

sales@aviteq.com.cn

Contact

Contact

addition to being used as a conveyor for small batches of bulk materials or powders, AVITEQ micro feeders are also often used to receive small, regular-shaped bulk materials from containers in large batches, and to complete tasks such as counting and arranging. AViTEQ is also an international leader in the production of such devices and drives.

Features & Benefits

Construct features

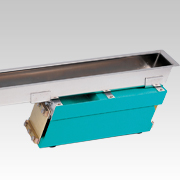

The micro feeder adopts the principle of double mass resonance, and its drive part contains components that generate vibrations, such as electromagnets, leaf spring groups, etc. The amplitude (double amplitude) generated by the work causes the material to be conveyed to be thrown slightly and theoretically produces a certain conveying speed, in addition, the actual conveying capacity is affected by the size of the conveying cross-section, the density of the material and other factors. When a micro feeder is used as a small parts conveyor, it is generally necessary to bolt a conveyor trough or conveyor track on the top of the micro feeder drive, so it is easy to disassemble and replace. The optimized design of the small feeder and the characteristics of its double-mass vibrating system ensure the stability of its conveying, regardless of the material load. The microfeeder drive is supported by rubber pads, and vibrations are virtually impossible to transmit to the surrounding environment.

drive selection

When selecting the right micro feeder drive, the customer must have a clear idea of the weight of the conveyor (also known as the working body) that will be mounted on the drive, and this weight must not exceed the allowable operating weight range for each drive. If the conveyor is supplied by the customer, then the accurate weight must be communicated after the order is placed so that the factory can adjust the frequency of the factory.

Construction

Accessories