+86-21 37047777 ext. 0

sales@aviteq.com.cn

Contact

Contact

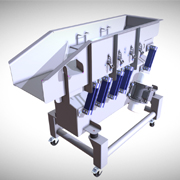

AViTEQvibrating-feederConveying, screening and dewatering are ideal for applications in food production that require the intake of light or fragile sensitive materials. The resonant feeder makes use of the principle of a two-mass vibrating system. The vibrating force acting directly on the counterweight is transmitted to the trough through the leaf spring group, forming a large amplitude on the trough. These devices are characterized by their compact design and low noise operation. Compared to conventional vibrating equipment with forced vibration, the drive required to perform the same process task can be much smaller. When an electromagnetic vibrator is used as the driving device, the resonant feeder can also be used as a bulk material metering device. The conveyor trough and sieve can be adapted to the customer's specific application.

Features and Benefits

Structural features

Design selection

The size of the product is determined by:

Key figures