+86-21 37047777 ext. 0

sales@aviteq.com.cn

Contact

Contact

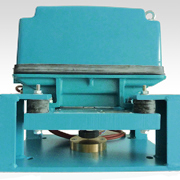

The AViTEQ Hopper-vibratorIt can be installed on the wall of the silo, and through periodic vibration and impact, the agglomeration and wall hanging phenomenon of the material can be eliminated or improved; It can also be used for vibrating inclined chutes (slots) and vertical pipes; It can also be used to better empty containers or to eliminate sticky materials (e.g. strainers). The more commonly used silo wall oscillators are vibrating motors and electromagnetic vibrators. However, when it comes to special and heavy-duty requirements, a structural silo wall oscillator can be used.

Features & Benefits

Construct features

In general, a single vibratory actuator can be used directly as a silo wall oscillator. But for better impact results, our Structural Silo Wall Oscillator is a better choice, which is constructed as follows:

Design selection

The size and type of vibratory actuator selection depends on:

Key figures