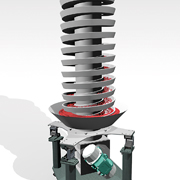

AViTEQ Vertical Feeder It is used for vertical conveying of bulk materials. The robust design of the vertical feeder can accommodate bulk materials in different production processes, which can be fine, coarse, and lumpy solids. Our vertical feeders are widely used in the chemical, pharmaceutical, food and other industries, as well as in the basic materials industry. These feeders can also be specially designed for product heat exchange (cooling/heating) or process treatment (drying). In addition to lifting the material upwards, the vertical feeder can also convey or move downwards.

Features & Benefits

- The conveying process is gentle on the material, which is an energy-saving and space-saving vertical conveying solution;

- Continuous operation requires little maintenance;

- It can be designed according to the requirements of hygiene and cleanliness;

- The material can be fully naturally cooled while conveying in the long-distance spiral conveying track;

- Cooling can be accelerated by direct heat exchange with external input air on demand, or by flow cooling at the bottom of the spiral conveyor track

The method of water is used as indirect heat exchange to improve the cooling efficiency;

- Conversely, the heating or drying of the material can be easily achieved by exchanging heat directly or indirectly with the material through high-temperature air, water or oil.

Construct features

The main components of the spiral vertical feeder include:

- Screw tops made of stainless steel or other special steels with a single or double layer of screw wings on the outside

- The receiving tray can be equipped with wear-resistant protection according to customer needs;

- According to the requirements, a high heat-resistant version is available, and the maximum allowable temperature of the material is 900°C

- Drive base with drive (can be designed to go up or down according to demand);

- According to the demand, it can be designed as fixed or movable;

- Depending on the requirements, it can be designed as open or closed (the enclosure can be a resonant or stationary design).

Design selection

The dimensions of the vertical feeder mainly depend on:

- The material to be conveyed (particle size, bulk density, surface moisture content, etc.);

- conveying capacity requirements;

- the vertical height difference required for conveying;

- Required process requirements (e.g. cooling, drying, etc.);

- Operating conditions

- On-site space arrangement

Key figures

- Effective conveying height difference: up to 8 meters;

- Outer diameter of the propeller: up to 1.5 meters

- Conveying capacity: up to 30 cubic meters / hour, related to the characteristics of the material;

- Drives: 2 inertial vibrating motors