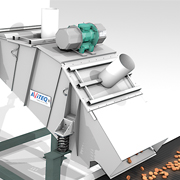

AViTEQ vibrates in a circular or elliptical trajectory to classify the material into several different particle size ranges; or remove large particles and small particles from the material; Or separate the impurities and foreign matter in the material. The vibrating screen adopts a specific vibration type for different materials and is designed according to the installation conditions on site. The vibrating screen screen is optimized for a specific screening task and can be screened in multiple layers at the same time.

Features & Benefits

- Long life, low operating cost, high operational stability;

- Cost-effective;

- Compact design;

- It can be designed to be dust-proof;

- According to specifications and different designs, a variety of screening properties can be realized;

- Wide range of screen shapes and specifications;

- Wide range of sieve materials (polyurethane, stainless steel, carbon steel, woven screens, perforated sieve plates, etc.).

Construct features

Its main components include:

- Screen box body with driver beam;

- screens;

- drives (electromagnetic vibrators, vibrating motors, or shakers);

- inlet and outlet;

- elastic support components;

- Sealed soft connections

Design Selection

Its dimensions mainly depend on:

- the type and characteristics of the material to be conveyed;

- the required screening effect and screening efficiency;

- Screening capacity per unit time;

- geometry requirements;

- the quality of the permissible installation;

Key figures

- Length: up to 9 meters;

- Width: up to 4 meters;

- Screening capacity: up to 750 m³/h

- Applicable drivers: electromagnetic vibrators, inertial vibration motors, exciters