+86-21 37047777 ext. 0

sales@aviteq.com.cn

Contact

Contact

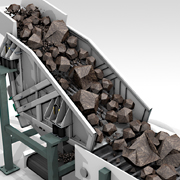

The AViTEQ is a rugged and high-intensity vibrating screen that is often installed downstream of hoppers or silos, belt conveyors or crushers as an integrated conveying and screening process. According to the needs of the application, the wear-resistant liner or the second to third section of the grid area can be used at the infeed position to protect the grid strip, and the grid strip changes from coarse to thin in the direction of material travel, that is, the strip between them gradually widens, which can effectively place the material jam. The application fields of this type of equipment include raw materials, stones, rare earths, coal and other heavy industries, and the maximum material side length that can be processed can reach 1000mm; Of course, it is also suitable for chemical, food and other relatively fine industries, and it can also be said that the equipment is suitable for all occasions of coarse and fine materials.

Features & Benefits

Wide range of applications;

Construct features

Its main components include:

Design Selection

Its dimensions mainly depend on:

Key figures