+86-21 37047777 ext. 0

sales@aviteq.com.cn

Contact

Contact

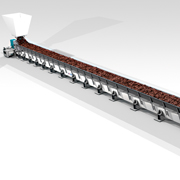

Sharp or high-temperature scrap (e.g. metal chips, foundry sand or stamping scrap) is often generated in many industrial processes, which often need to be transported through long underground corridors to the downstream process. The problems often encountered with traditional belts are high wear and spillage, resulting in high maintenance costs, frequent cleaning of ditches or corridors, and production interruptions. In such cases, the AVITEQ long-distance trough feeder would undoubtedly be a better choice.

Features & Benefits

Construct features

The conveyor trough is connected to a vibrating frame by means of a guide leaf spring, and the conveyor trough itself is housed on a set of compression springs side by side, which isolates 99% of the vibrating forces from the environment, while the overall structure and foundation of the feeder can be made very small.

Design selection

The dimensions of the long-distance feeder mainly depend on:

Key figures